Insulating roof tile underlays

There is a new category of composite insulating roof tile underlays that:

- are marketed as underlays;

- installed as underlays i.e. over the roofing structure and below the slating or tiling;

- act as underlays with their prime function being to provide a barrier that reduces the wind uplift load acting on the slates or tiles and as such are tested as composites and labelled as underlays in accordance with BS5534 (British Standard for Slating and Tiling) Annex A;

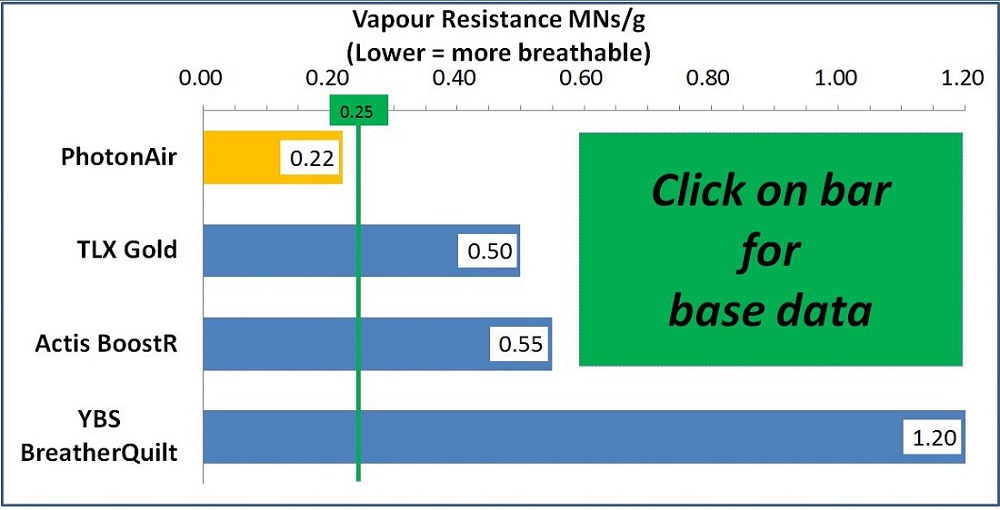

PhotonAir is the ONLY low resistance (LR) insulating underlay amongst these four LABC registered products. (Data as at 1st February 2017)

BS 5250 (Code of practice for control of condensation in buildings)

States that in warm pitched roofs only LR underlays remove the risk of interstitial condensation forming without the need for any associated ventilation to roof voids.

BS 5250 defines two types of roofing underlay as:

- HR (High Resistance) having a water vapour resistance greater than 0.25 MN.s/g.

- LR (Low Resistance) having a water vapour resistance not exceeding 0.25 MN.s/g.

HR underlay

BS 5250 further states: "In roofs with an HR underlay.., whatever form of external covering or ceiling is provided, there is a risk of interstitial condensation forming on the underside of the HR underlay; to avoid that risk, an AVCL should be provided on the warm side of the insulation, and ventilated voids should be formed between the underside of the underlay and the insulation. Each void should be at least 25 mm deep and be vented at both high and low level."

The requirement to ventilate below a high resistance (HR) insulating underlay negates the thermal benefit it gives to the roof structure.

LR underlay

However, for warm pitched roofs constructed with a LR underlay, BS 5250 has NO requirement to ventilate the underside of the underlay and there may also not be the requirement to provide an AVCL on the warm side.

PhotonAir low resistance (LR) insulating underlay upgrades thermal performance without the risk of condensation.